GeoBlack

The excellent Black

GEOBLACK® goes upmarket.

The black-on-black system enhances design.

Characteristics and performance

-

Thin dry-film, non electrolytic

-

Strong resistance to chemical attack: solvents, fuels, brake fluids (VDA 621 412)

-

Possibility of extremely high chemical resistance, including wheel cleaning solutions, with GEOKOTE® black topcoat

-

Water-based chemistry

-

No hydrogen embrittlement

High resistance to corrosion

Salt Spray Test (ISO 9227) > 1000 hours without red rust

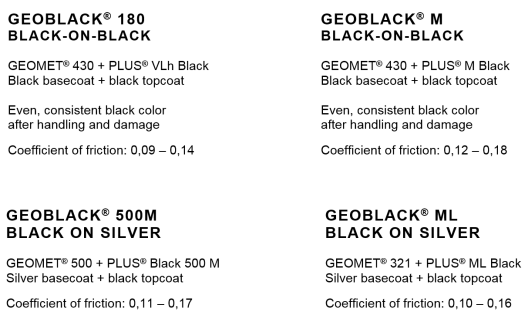

Results may vary depending on substrate, geometry of parts, type of application processes and coating thickness. Coefficients of friction according to ISO 16047.

Application process

GEOBLACK® can be applied by Dip-Spin, Dip-Drain-Spin using bulk or rack

Health and Safety

- Aqueous dispersion

- Complies with REACh

- Complies with the 2011/65/EU and (EU) 2015/863 directives

Main worldwide specifications

- BOSCH (0 204 Y81 074 Code G finish 6)

- CHRYSLER (PS-5873 BLACK)

- FIAT (9.57513)

- FORD (WSS-M21P39-A3, WSS-M21P49-A3)

- GM (GMW 3359)

- JAGUAR CARS & LAND ROVER (ST JLR.50.5050)

- JOHN DEERE (JDM F13)

- INTERNATIONAL TRUCK (TMS 4520)

- IVECO (18-1101)

- VOLVO Cars (VCS 5737,19)

- VOLVO Trucks (STD 121-0003)

International standards

EN ISO 10683 – Fasteners-non-electrolytically applied zinc-flake coatings

EN 13858 - Non-electrolytically applied zinc-flake coatings on iron or steel parts

ASTM F1136 / F1136 M - Zinc/Aluminum Corrosion Protective Coatings for Fasteners